Week 4: Electronics Production

Wednesday 17/02/16 It was a pretty straightforward day, listening to Neil's lecture, googling unkown territories and taking notes.

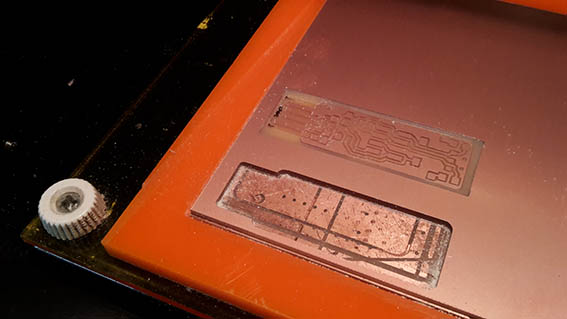

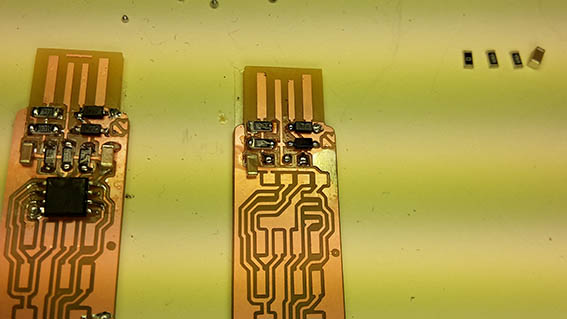

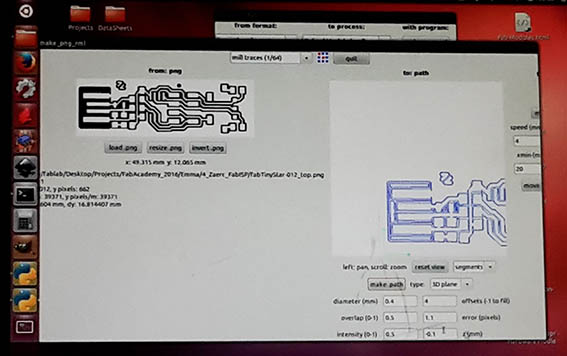

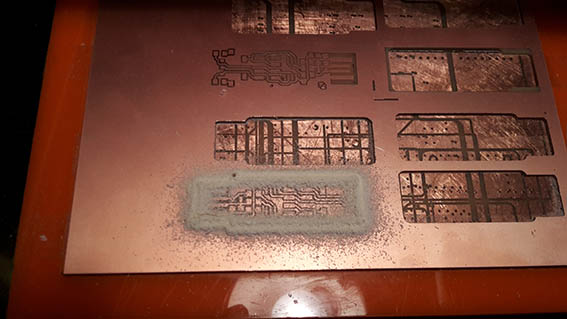

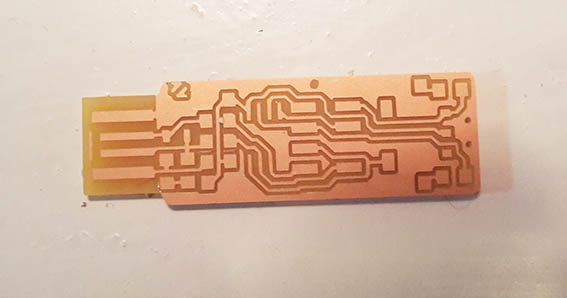

On Thursday 18/02/16: Emma demonstrated the use of the Roland Modella and the soldering. I was almost shocked from the small size of the components that we had to solder. I was sure that those operations are not done by hand. While waiting for my turn to cut, I started welding on a test piece where I made mistakes about the orientation of specific components like the microcontroller and had to detach and re-attach it. You can see an image of the milling setup below. I set the z to 0,15 because I needed it to cut a little bit deeper than usual. I wanted to make sure that it would definitely cut through the copper without leaving traces.

For cutting out the board I changed the endmill from 1/64 to 1/32 and I went on to change the settings and proceed with cutting which was something that the machine didn't like at all. It wouldn't start to cut. Thankfully, Zaerc was near me and he started typing commands in the Ubuntu terminal. I honestly have absolutely no idea what they were and as much as I tried to observe, he was just too quick for me! In the end we ‘killed’ all processes in the terminal and restarted the Modella a couple of times until it cut around my board smoothly using the settings below.

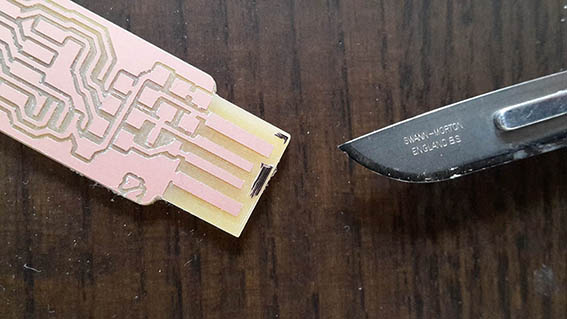

Some left over copper was easily scraped off with my trusted scalpel. I was on track to start ‘stuffing’ on Monday.

Friday 19/02/16: There was not much I could do from home so I revisited my Coral Light drawing and fixed some things that needed to be changed. I corrected the link to it on my website.

On Saturday 20/02/16: I played around in Rhino to finalize my Incense Burner rendering and I spent a LOT of time on working out how to draw the hinge. It was something that appeared simple but for some reason it took me a very long time!

Sunday 20/02/16: I addressed some issues that I had with my website and I managed to align sentences and create larger ‘divs’ with the lesson titles.

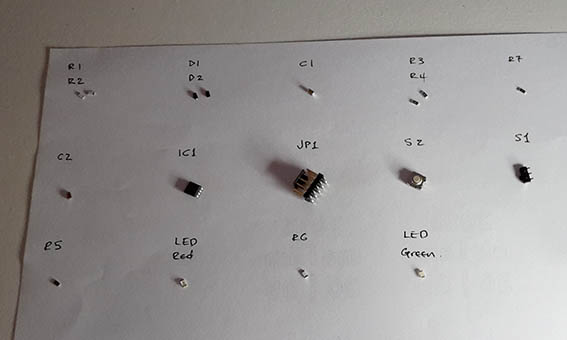

On Monday 20/02/16: I arrived at the Fab Lab relatively early. I wanted a head start just in case things went wrong. I had read some descriptions from previous years and it seemed that the ISP was quite tricky to make. My first obstacle was finding the components that I needed. Not only did I not understand what each item was, they were not even labelled the same way as described in the documents I was reading. I mean, it must be a piece of cake for a person with a bit of background in electronics but for me it was a puzzle!

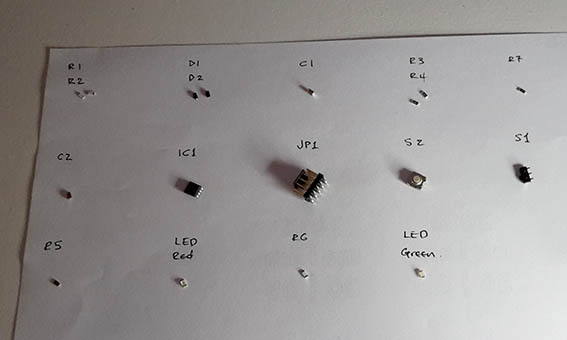

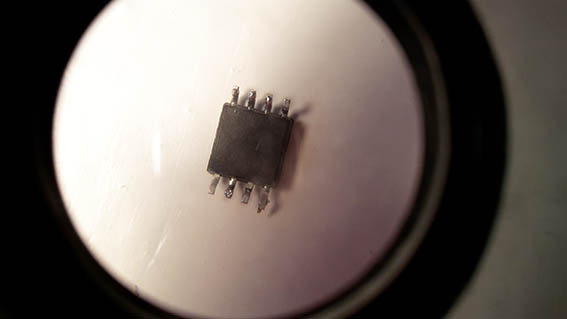

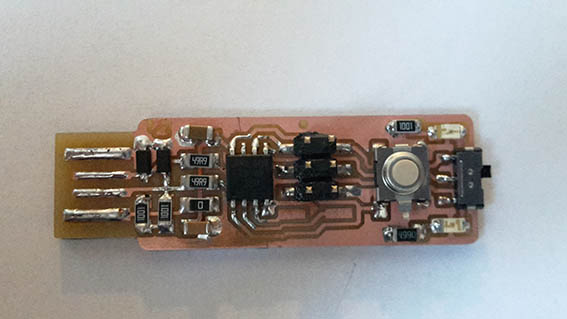

I started documenting the components I needed with my phone camera so I could re-locate them if I needed them again. I made a ‘map’ of all the components and I started soldering feeling very confident about my skills!

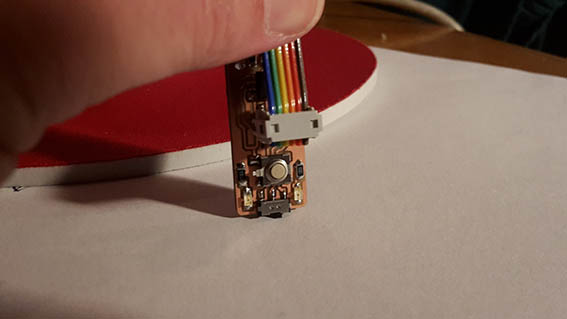

As it turns out Monday was just one of those days when nothing goes right (I was sure about it when I got on the wrong bus on the way home). Although I had found a pretty convenient way to work like using the magnifying glass with the florescent light, my battery operated soldering iron and sticking the ISP on my sketchbook in order to be able to rotate it, things were going pear-shaped. I was dripping solder all over the ISP, I stuck an 8 pin connector instead of a 6 pin one.

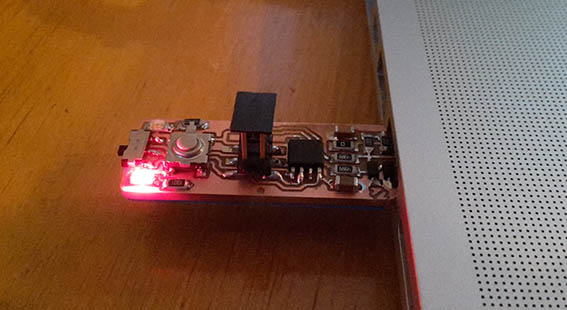

After a lot of struggle I had finished. I put the ISP in my computer and the LED lit up. I thought I was ready to program.

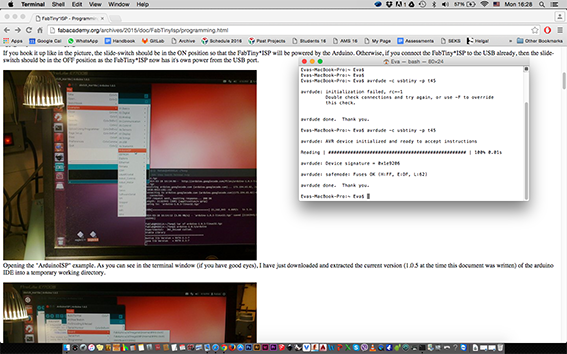

Emma asked me to check the connections with the multimeter and make sure that everything was connected fine. I had seen multimeters before, I even bought one but I never operated one. So I wasn’t clear how to check it. In the end, I somehow decided that I did enough verifying and that I could proceed with the programming. Only to be faced with another shock… I understood close to nothing from that tutorial. As a person without any experience of programming, electronics or even basic use of terminal commands, I was completely baffled and quite disappointed. For example the sentence ‘You will need a working build environment that includes "make", "avr-gcc" and "avrdude", setting this up depends on your operating system and is unfortunately not covered here.’ is not at all clear to a beginner, it does not even give a clue of where to start.

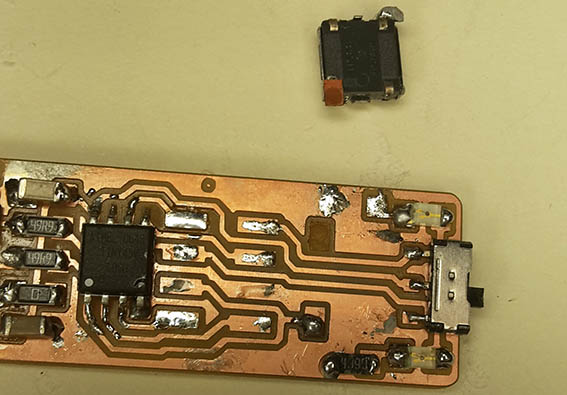

Emma tried to help me with programming only to figure out that there was indeed something wrong with the ISP. She came to the conclusion that I had dripped some solder on the push button which messed up the connections and that I had to replace it.

I went to the soldering station which was surely the busiest corner of the Fab Lab and I tried to remove the push button as Neil described. Hold the item you want to remove with the tweezers and heat the board until the rest drops down. That resulted in a resistor coming out, the connector sticking to my trousers and the push button removing a piece of the copper with it. I quickly soldered them back on and re-tried programming until it was clear that the Fab Lab would close and I had to go home.

Tuesday 21/02/16 I was in the Fab Lab quite early again because I had a feeling that I would have to (and was secretly hoping to) mill another board.

Emma advised me to change the microcontroller and I did but it still didn't work. Then we removed a resistor but without any luck. Finally, she said to start making a new one. I was actually quite relieved because I couldn't believe the mess I had made of the first one.

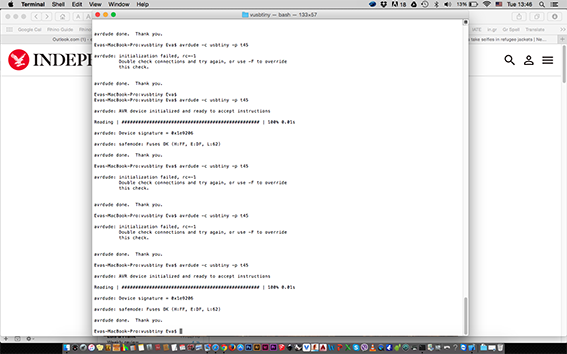

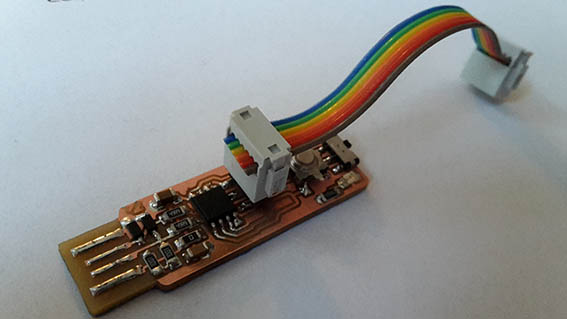

I milled quite easily and proceeded with soldering after going through the same procedure of locating the components. At least this time I had the photographs to help me. I feel that I have done a pretty clean job, finally deciding that I will be using the thinnest soldering iron and the thinnest available solder thread. I found it very helpful to heat the copper first and then solder as we were advised on Thursday. So everything seemed in place and I asked Emma to clarify the Multimeter operation. Things seemed fine, so with the help of Emma I proceeded to read the tutorial again in order to program it. I really did not understand much of the tutorial steps and I surely could not complete this by myself… The biggest problem that we faced was that it was not communicating with the computer in a stable manner. At first it would only be recognised on Emma's computer but not mine, then we thought we should be pressing the connection with our fingers, but again it wasn't always succcessful… Until Emma noticed that I had put the wrong resistors in. This time I carefully and methodically heated and replaced the components and proceeded once again to program.

I really don't know how many ‘Yikes’ and ‘Initialization Failed’ warnings I got. It read it for five times in a row and then it stopped again! The strange thing was that it would read it once and not read it for the next ten times…On top of that the LED light stopped working, but Emma thought that I would manage to program it. I added some cardboard at the back and I plugged it in pushing it with my finger - which made the light turn on.

That was when Emma had a flash herself… realizing that the slide switch was faulty! When we were pushing it against the table, it worked perfectly. When we held it in the air it was not recognised. Victory! We programmed by holding it on the table and I then replaced the switch.

After that we tested it 5-10 times and it remained in tune. In the photo above you can see Emma pushing the switch on the table in order to work. At this stage, I feel the need to thank her for all the time she devoted to making my ISP work.

Looking back and also thinking about what the future holds, I don't seem to have big problems with the machines since I have my share of experience with similar tools. I am also quite confident about my hand skills, but I am helpless when it comes to electronics. I need to be clearly introduced to the basics and guided through the right steps in order to fill in my blanks. I was never taught anything like this and definitely have never worked on similar devices. To address this weakness is the main reason I joined Fab Academy. Tutorials are a great way to guide one through the necessary steps, but they are rarely accurate and more often than not the writer assumes that the person reading has pre-existing knowledge. I do however look forward to the rest of the course with optimism!

Electronics Production Lecture Back to Weekly Assignments Home